CNC aluminum parts are widely used in the new energy vehicle industry. These parts are made using computer-controlled machines, ensuring precision and efficiency. In new energy vehicle industry, CNC aluminum parts are used for various purposes:

Battery Components: Lightweight and strong parts for battery casings and cooling systems.

Motor Housings: Aluminum parts for better motor performance and heat dissipation.

Chassis and Structure: CNC parts make the vehicle safer and more durable.

Suspension Components: They ensure a smooth and stable ride.

Charging Connectors: CNC machining provides reliable charging options.

Power Electronics: Aluminum heat sinks for efficient heat dissipation.

Interior and Exterior Trim: Adds modern style to new energy vehicle industry.

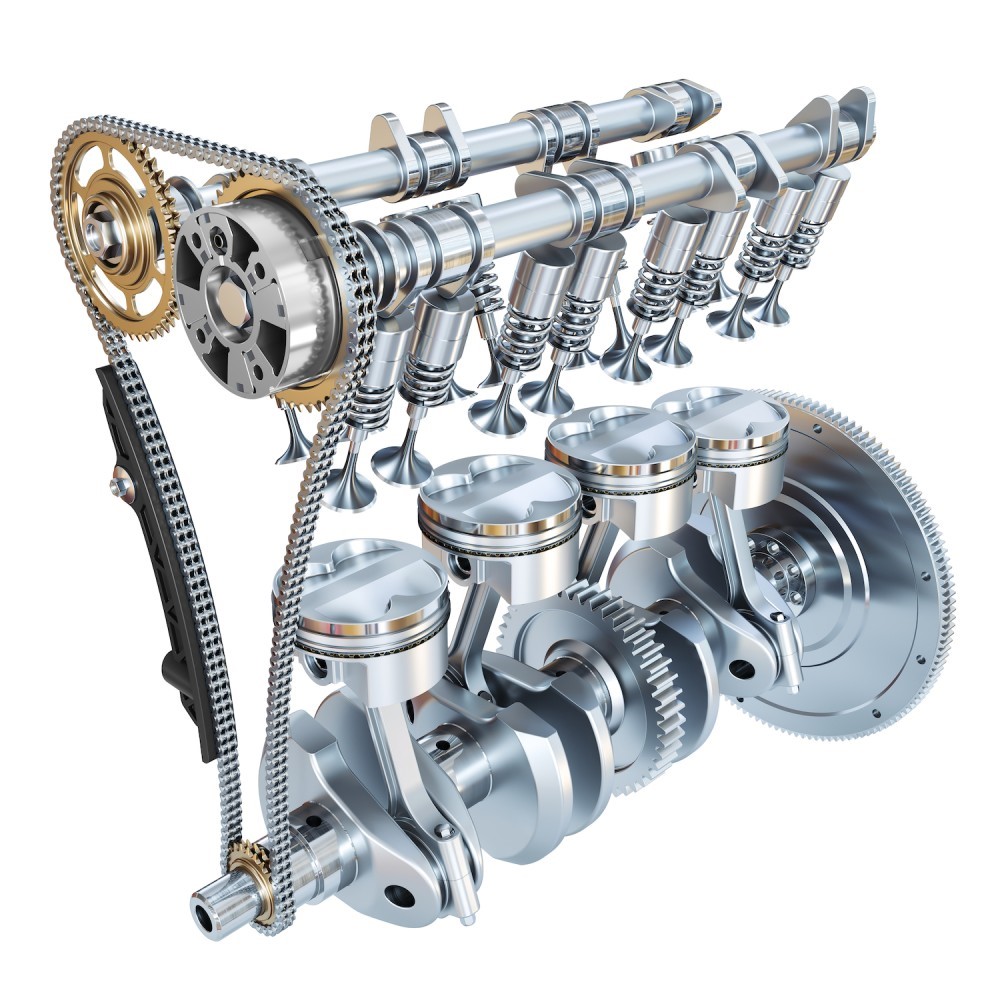

Transmission Components: CNC parts ensure smooth power delivery.

Wheel and Brake Components: Lightweight aluminum wheels improve handling, and brake parts are durable.

Using CNC aluminum parts in new energy vehicle industry has benefits like weight reduction, improved energy efficiency, and better performance. As the new energy vehicle industry grows, the demand for precise CNC-machined aluminum parts will increase, driving further advancements in technology.

ch

ch English

English